Our equipment

| № | Crane type (brand) | SlNo | Lifting capacity (t) | Handling radius (m) | Location |

| 1. | Kirovets |

12 |

10 |

30 |

Berth № 26 |

| 2. | Albatross |

5 |

10 |

30 |

Back area of berth № 31 |

| 3. | Albatross |

22 |

10 |

30 |

Railway front line of berth № 31 |

| 4. | Albatross |

23 |

10 |

30 |

Berth № 30 |

| 5. | KONE |

8 |

30/12/5 |

25/45/48 |

Between slipway and dock repair shop |

| 6. | KONE |

7 |

30/12/5 |

25/45/48 |

Berth № 29 |

| 7. | Kirovets |

1 |

32/16/5 |

17/30/33 |

Railway front line, warehouse of berth № 29 |

| 8. | Kirovets |

2 |

10 |

30 |

Berth № 31 |

| 9. | Kirovets |

6 |

20/10/5 |

17/30 |

Pier № 2 |

| 10. | Kirovets |

9 |

10 |

30 |

Pier № 2 |

| 11. | Ceretti |

3 |

30/12/5 |

25/45/48 |

Railway front line, warehouse of berth № 29 |

| 12. | Ceretti |

4 |

30/12/5 |

25/45/48 |

Railway front line, warehouse of berth № 29 |

| 13. | Kirovets |

10 |

20/10/5 |

17/30 |

Pier № 1 |

| 14. | Kirovets |

15 |

10 |

30 |

Slipway area |

| 15. | Kirovets |

18 |

10 |

30 |

Slipway area |

| 16. | Ceretti |

11 |

30/12/5 |

25/45/48 |

Pier № 1 |

| 17. | Albrecht |

20 |

10 |

30 |

Between railway front line and Machine assembly shop |

| № | Crane type (brand) | SlNo | Lifting capacity (t) | Travel type | Width of span (m) | Lift height (m) | Location |

| 1. | К-09 | 21 | 12,5 | Rail | 16 | 10 | Steel warehouse |

| 2. | DLT100 | 24 | 50*2=100 | Wheel | 32 | 18 | Back area of berth № 29 |

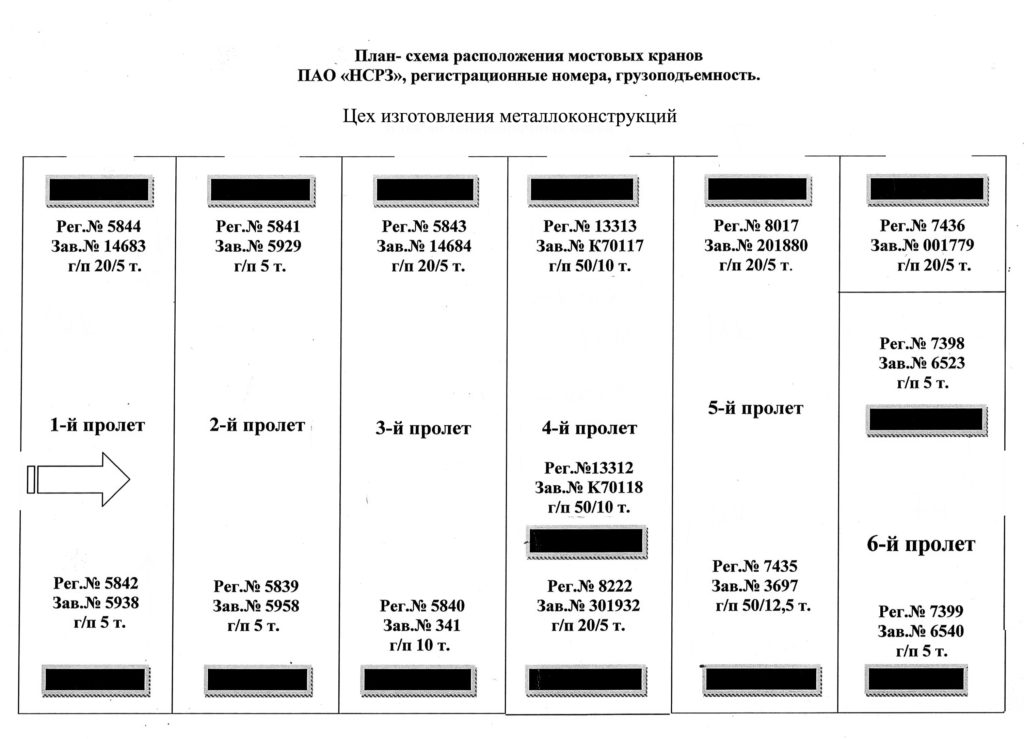

Metalwork shop

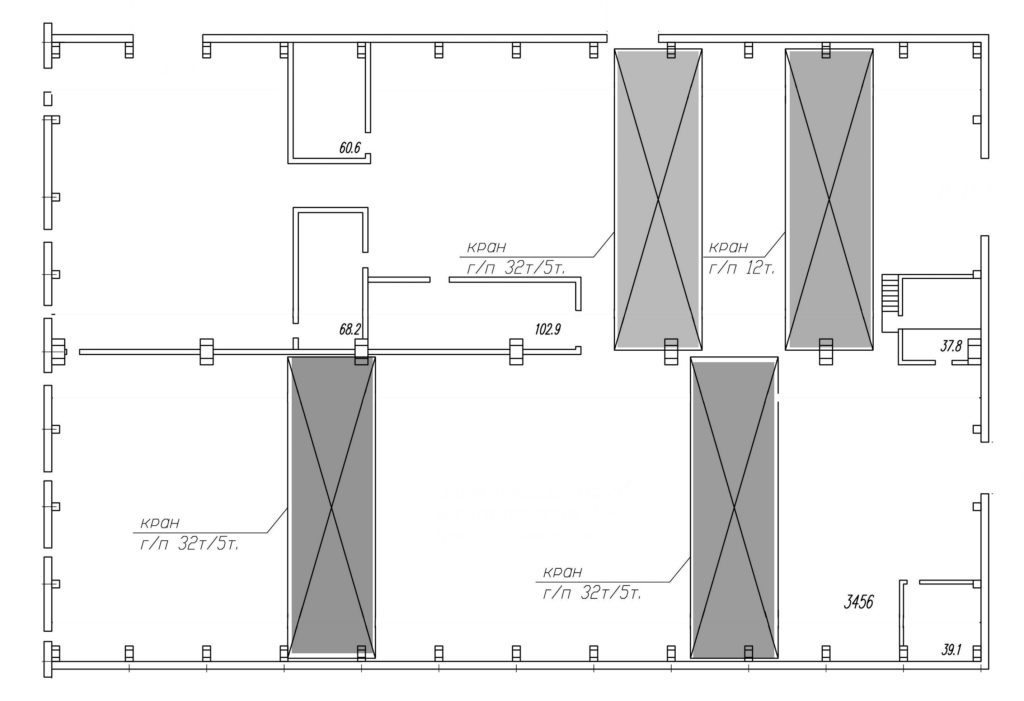

Dock repair shop. Location and lifting capacity of the cranes.

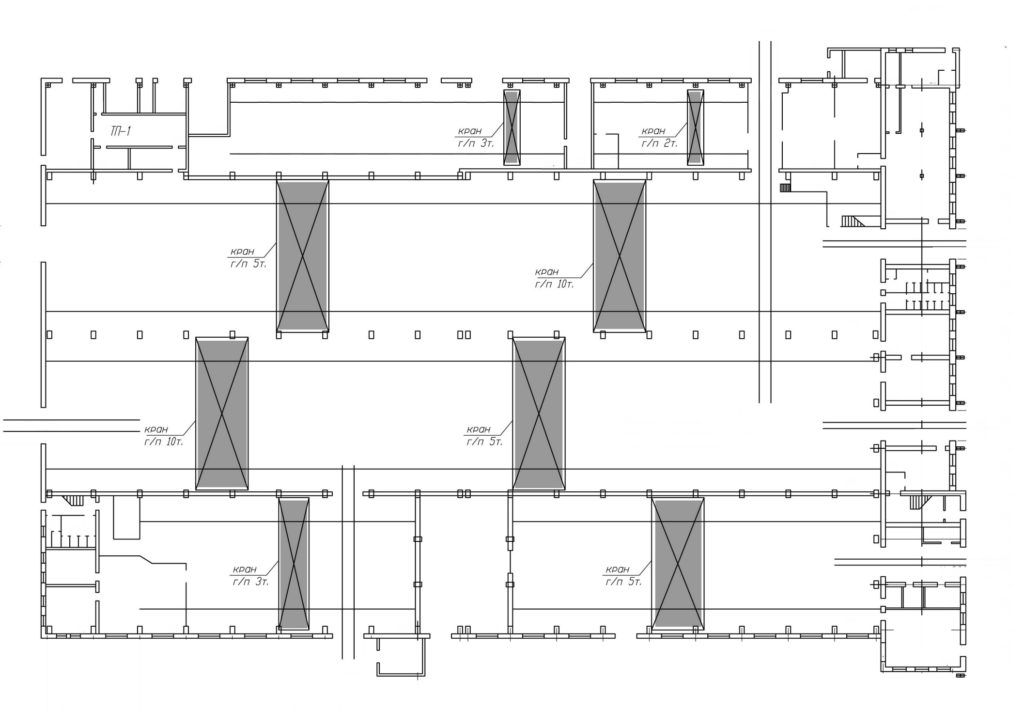

Hull-welding shop. Location and lifting capacity of the cranes.

|

List of welding equipment of PJSC “NSRY” |

|||||

|

Item |

Brand, |

Q-ty, |

Year of housing |

Specifications |

|

|---|---|---|---|---|---|

| № п/п |

1 |

2 |

3 |

4 |

5 |

|

1 |

Beam welding machine |

“Corimpex” BWM/3000-1000 |

1 |

2010 |

Beam depth, mm 200-3000 Wall thickness, mm 5-30 Beam width, mm 160-1000 Flange thickness, mm 6-40 |

|

2 |

Semiautomatic welding machine |

Kemppi FAST MIG |

40 |

Rate power, kVA 18 Load cycle%-100 Welding voltage, V 10-39 Welding current, А 10-400 |

|

|

3 |

Semiautomatic welding machine |

Kemppi KempoMIG |

20 |

Rate power, kVA 18 Load cycle%-100 Welding voltage, V 10-39 Welding current, А 10-400 |

|

|

4 |

Semiautomatic welding machine |

FastMIG MSF33+FastMIG KM400 |

10 |

Rate power, kVA 18 Load cycle%-100 Welding voltage, V 10-39 Welding current, А 10-400 |

|

|

5 |

Semiautomatic welding machine |

FastMIG MXF65+FastMIG KM420 |

30 |

2016 |

Rate power, kVA 18 Load cycle%-100 Welding voltage, V 10-39 Welding current, А 10-400 |

|

6 |

Semiautomatic welding machine |

DAEWOO ARC-500 (DW 500) |

20 |

Rate power, kVA 18 Load cycle%-100 Welding voltage, V 10-39 Welding current, А 10-400 |

|

|

7 |

Converter |

Profi ARC-315 |

50 |

Rate power, kVA 12 Load cycle %-60 Welding voltage, V В 0-30 Welding current, А 20-300 |

|

|

8 |

Arc welding machine |

АДФ-1000 УЗ с ист. ВДУ-1250УЗ |

10 |

Rate power, kVA 75 Load cycle %-100 Welding voltage, V 22-44 Welding current, А 10-1250 |

|

|

9 |

Double-headed automatic arc welding machine |

2ТС-16-2-УЗ с ист. ВС-600 |

1 |

Rate power, kVA 96 Load cycle %-100 Voltage ХХ, V 75 Welding current, А 10-180 |

|

|

10 |

Automatic arc welding machine |

ТС-16-2-УЗ с ист ВДМ-1202 САУЗ |

20 |

Rate power, kVA 18 Load cycle%-100 Welding voltage, V 10-39 Welding current, А 10-400 |

|

|

11 |

Argonarc welding machine |

Kemppi |

10 |

Rate power, kVA 12,5 Load cycle % 30-100 Welding voltage, V 10-80 Welding current, А 400-270 |

|

|

12 |

Welding key for welding drums |

EuroTech ETW-075 |

1 |

Vertical traverse -6000mm, horizontal traverse 3650mm, longitudinal travel of leg – 16000mm, welding current source power – up to 1250А, rotators- 4 ea electric powered with control panel, 8 ea w/o drive unit. Rotator lifting capacity – 20000 kg, rotation rate 100-1000 mm/min, rotator cylinder diameter – 400mm. | |

|

13 |

Welding machine for stud welding |

Koco Elotop 502 |

2 |

2014 |

Stud diameter 3-8 mm, max. Welding current -450 А. |

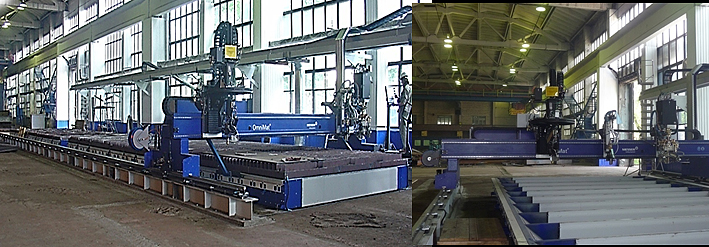

Gantry span: 7000 mm

Track length: 36000 mm

2 cutting tables with an area of 14000х5000 mm

The gantry is equipped with 4 tools :

1. Plasma cutting assembly (SKEW-AXIS-BEVEL-ROTATOR)

– vertical cutting for thicknesses from 3 to 50 mm

– beveling at an angle up to 42° for a thickness of 6 to 40 mm

2. 3-hose machine cutting torch ALFA MS 4450/250

Used for vertical oxy-cutting for max thickness of 200 mm

3. High precision center punch with max precision of center punching at 6,000 mm per min

4. Rotating DKS assembly with three torches for gas cutting of plates. CNC controlled cutting pattern. Capable of performing straight, contour, Y and K bevel cutting

Steel thickness:

80 mm for horizontal cuts with three torches

150 mm for vertical cuts with one center torch

Angular displacement of side torches 15-55°

Lateral displacement of side torches 0-55 °

Machine for automatic air-plasma and oxygen cutting with numeric program control (model «FLAGMAN» ППлЦ-1,5»).

Portal machine ” FLAGMAN ” is intended for figured cutting of parts from sheet metal in automatic mode under control bythe internal computer. The machine can operate independently and also as a part of automated lines. Depending on the nature and thickness of the cut metal the machine can perforn either plasma or oxygen cutting. The machine is equipped with modular attachment unit for plasma and gas cutters.

Installed industrial computer enables the remote operator to make manual programming of free shaped parts and cut them.

The system also allows to perform direct control from a personal computer and high level PC (via serial interface), cutting and shaping of parts, prepared with the assistance of software and hardware tools of the automated preparation and transfer of control programs.

-

Machine

(country of manufacture)

Model /

Trade mark

Accuracy class

Q-ty (unit)

Main technical characteristics

Photocopying thermal cutting machine (USSR) ПКФ 2,5-2-3

2

1

S=5-100 mm, sheet size 8000х2500 mm Plasma cutting machine (Russia) «Флагман» ППлЦ – 2,5

–

1

S=4-100 mm, cutting speed 5-10000 mm/min. Portable gas-cutting machine (USSR) «Смена»

–

2

S=5-300 mm, cutting speed 50-1600 mm/min. Portable gas-cutting machine (USSR) «Радуга»

–

5

S=5-3100 mm, cutting speed 50-1600 mm/min. Articulated-arm gas-cutting machine (USSR) АСШ – 70

–

2

S=5-300 mm, cutting speed 50-4600 мм/min.

Manufacturer: VOORTMAN (NETHERLANDS) 2011, сommissioning – 2012.

NSRY blank preparation section is equipped with a Vootrman V630® machine for making holes in steel profiles and formed parts. It is equipped with one horizontal drilling module and perfectly fits the needs of the yards with high requirements for small size equipment.

Capable of operating on all sides of profile. An automatic tool changer and machine software capabilities enable simultaneous work on multiple items.

Number of drill spindles: 3, with automatic tool changers.

Spindle speed: 100÷2500 RPM (stepless)

Tools: drill bits (HSS) – 5÷40 mm, drill bits (hard alloy) – 13÷32 mm

Threading: М6÷М24

Centering: 3 sides

Numbering unit: VN36 (36 characters)

Min/max. profile height: 10 ÷ 600 mm

Min/max. profile width: 50 ÷ 1,250 mm

Min item length: 1,500 mm

Types of processed profiles: bar, angle, tee, channel, double tee, square pipe.

Manufacturer: VOORTMAN (NETHERLANDS) 2011, commissioning – 2012.

Cutting blade Voortman VB1250 is used for cutting rolled steel sections. Key feature of Voortman cutting blades is hard and heavy machine frame, high speed and quality of cut.

Cutting blade VB1250 is included in Split-system of sawing and drilling lines.

Min/max profile thickness:10÷600 mm

Min/max profile width: 50÷1250 mm (straight cut)

Max. profile width / angle of cutting ±30° 1000 mm

Max. profile width / angle of cutting ±45° 850 mm

Max. profile width / angle of cutting ±60° 500 mm

Types of processed profiles: bar, angle, tee, channel, double tee, square pipe.

Max transfer system load: 400 kg/m

Speed of cutting: 40÷120 m/min

Drive power: 11 kW

Sheet dimensions: 9800х67х1,6 mm

For drilling holes in profiled metal Voortman V600® machine is installed in blank section. It is equipped with one horizontal drilling module. Around-the-part machining of profile is possible. Simultaneous machining of several items is acceptable due to device for automatic tool change and options of the machine software.

Technical specification

1 VACON 110 computer system

– Industrial computer PENTIUM with hard disc;

– Color monitor 15”;

– Industrial-applicated keyboard;

– CD-rom driver;

2 Hydro station

Pump: 3 kw, max pressure: 160 bar

3 Positioning table

Width: 300 mm, length: 21,000 mm

4 Supports

Length: 1,500 mm

Operational height: 920 mm

5 Drilling device

Drill diameter: 8-40 mm

Carbidic drill diameter: 13-32 mm

Cutting thread: M8-M24

Quick coupler: SK40

Automatic change of tool: 5 positions

Advance and positioning: (Y&Z): servo drives, inverters

Spindle rotation: stepless 100-2500 rpm

Lubricant: internal cooling with oil/air

Center adjustment with spots: yes

Electric supply: 3 x 400В + N + PE 50HZ

Environment temperature: 0 – 35°C max (HR 95%)

Technical Specification:

Max weight of beam: 200 – 3,000 kg

Thickness of wall: 5-30 mm

Flange: width 160-1,000 mm, thickness 6-50 mm

Max. depth of correcting shrinkage distortion = 28 mm with flange width 300 mm

Max. depth of correcting shrinkage distortion = 40 mm with flange width 700 mm

Max. depth of correcting shrinkage distortion = 50 mm with flange width 1000 mm

Total height of the unit: 5,950 mm

Max weight of beam: 1.0 t/m

Min. length of beam: 6,000 mm

Max length of beam: 16,000 mm

Move of hydraulic cylinder: 900 mm

Beam of variable cross section: height difference between two columns must not exceed 900 mm. Max angle 20°.

Tacked spot is not necessary. It is required to perform once tacked spot of wall and flange.

Input/output systems with power-driven rollers: speed = 12 m/min

Working pressure: 9 t, adjustable

Process: one-head automatic welding under melt with forked welding rod.

Welding speed: 0.2 up to 2.3 m/min

Electric power supply: 3 x 400v AC current + neutral + 50 Hz

Semiautomatic, hydraulically manipulated twin pillar belt-saw machine is suitable for cutting steel structures and profiles.

The machine allows to cut material at an angle from -60 to 60 degrees. Due to the massive design it enables cutting parts from various materials, including stainless and tool steel, both profiles and solid billets.

Standard machine instrumentation:

– machine is equipped with two massive support rollers for the cut pieces;

– the frequency converter;

– the saw blade;

– a set of tools.

Operational cycle:

After manual adjustment of the arm working position operator starts the cycle with a switch on the control panel.

The speed of the arm into the cutting area is regulated by the operator through the throttle valve. After cutting the arm reaches its top operational position and the drive of saw blade stops. The clamps are opened. The operator changes the work piece manually. The control system transfers information about correct stretch of a blade, properly closed blade jacket and the load of the saw blade drive during cutting, which helps for adjusting the feed rate of the arm in the work piece.

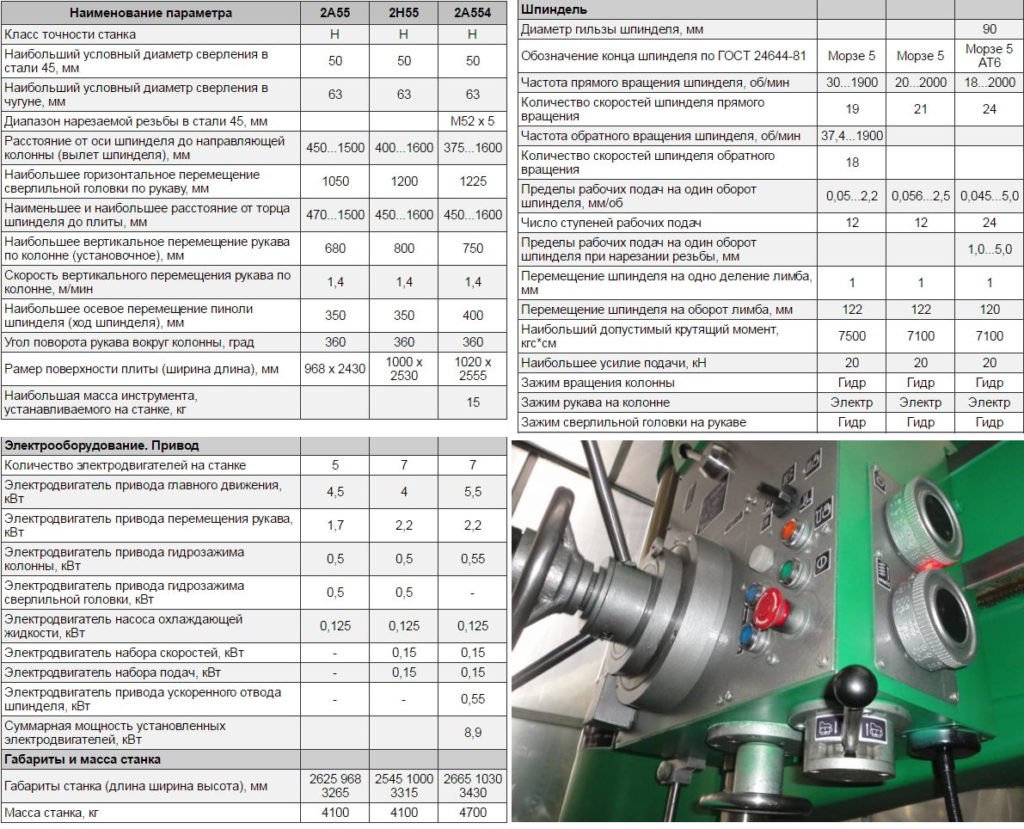

These machines can drill holes with diameter up to 50 mm in steel and up to 63 mm – in cast iron workpieces. As stated above, machine 2А554 is able to cut an internal thread with diameter of М52х5 for steel and М54х4 for cast iron.

Parameters specified in the passport include distance from column to spindle axis (375-1600 mm) and the distance from spindle nose to working table (450-1600 mm). These characteristics mean that the machine is allowed to perform the processing of quite large items.

Speed of lifting the cross beam along the column is 1.4 m/min. The cross beam along with the column can rotate up to 360º.

Dimensions of workpieces that can be processed on radial drilling machine 2А554 are determined by the size of the work table (102х255,5 mm). To expand functional capabilities of the machine the drilling unit can be completed with an extra tool with weight not exceeding 15 kg.

|

Machine (country of manufacture) |

Model / Trade mark |

Accuracy class |

Q-ty (unit) |

Main technical characteristics |

|

Hull-welding workshop |

||||

| Hydraulic plate stamping press |

ПА3236Ф1 |

– |

1 |

Press power 400 t. |

| Plate-shearing machine (Finland) |

“JAROMET” |

– |

1 |

S=25 mm; В=6000 mm . |

| Plate-shearing machine (Yugoslavia ) |

МВ(Ц)С 3100/32 |

– |

1 |

S=32 mm ; В=3100 mm . |

|

Steel structures fabrication shop |

||||

| Hydraulic plate stamping press (USSR) |

ПА3241 |

– |

1 |

Press power 1250 t. |

|

Electrical assembly shop |

||||

| Guilliotine shearing machine (USSR ) |

– |

– |

1 |

S=4 mm ; В=1600 mm . |

| Guilliotine shearing machine (USSR ) |

Н3118 |

– |

1 |

S=5 mm ; В=2100 mm . |

The machines of 872м type are designed for cold metal cutting. Cutting can be carried out both in a plane perpendicular to the workpiece axis and at any angle up to 45 degrees. The machine can perform cutting round metal, square and other profiles.

Accuracy class: Н

Max. diameter of workpiece , mm 250

Max. length of cut workpiece, mm 350

Capacity, kW: 1,5

Dimensions (L_W_H), mm: 1470_690_885

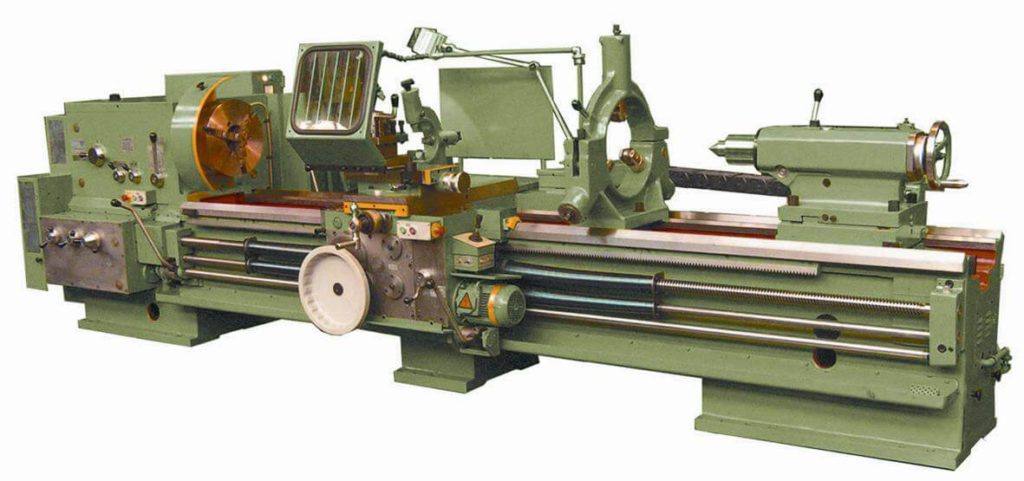

Weight of machine including removable accessories, kg: 600

esigned for performance rough and final turning cylindrical, conical, and complex surfaces – both internal and external. Turning-and-boring machine 1516 is used for drilling, squaring and reaming of the central holes in various workpieces made of ferrous and nonferrous metals.

Max. diameter of processed item, mm – 1600

Max. height of processed item, mm – 1000

Chuck size, mm – 1400

Max. weight of processed item, kg – 8000

Chuck rotation frequency, min-1 1 – 250

Stages of chuck rotation frequency – 2

Chuck rotation frequency control – stepless

Max. torque strength on the chuck, kN*m – 25

Main gear motor power, kW – 55

Vertical displacement of cross beam, mm – 660

Beam displacement rate, m/min – 0,45

Top slide:

Slide horizontal traverse, mm – 950

Toolhead slide vertical traverse, mm – 700

Max. permissible cutting pressure, kN – 35

Max. toolhead slide sweep angle, deg ±45

Number of turrethead positions- 5

Side head with feed box:

Head vertical traverse, mm – 1 000

Toolhead slide horizontal traverse, mm – 630

Max. cutting pressure, kN – 25

Number of blade holder positions – 4

Number of saddle feeds – stepless

Rate of slide adjustment travel, mm/min – 2000

Dimensions (L х B х H), мм 3170 x 3030 x 4100

Weight, kg – 18100

allows to perform the following operations:

– sharpening of cutting tools with height up to 100 mm, made of high speed steel or equipped carbide blades;

– sharpening of drills with diameter of 12 to 50 mm;

– sharpening of various tools used for mechanical works;

– grinding operations – deburring, beveling the surface of the item or other types of mechanical works;

– smoothing the items with abrasive tape;

– polishing.

Intended for sharpening of cutting tools, drills and bench tool

Dimensions, mm: 570x390x390

Main gear motor power, kW: 0.75

Weight of machine including removable accessories, kg: 70

Accuracy class: Н

Max. chuck rotation frequency, r/min: 2840

Is designed for grinding external and internal cylindrical or conical surfaces by means of plunge-cut and longitudinal grinding and also for grinding of flat surfaces of parts such as washers and for grinding the ends

Height of centers, mm – 240

Max. dimensions of processed item, mm:

– diameter 400

– length 1000

Dimensions of grinded hole, mm:

– diameter 30-200

– max length 125

– Max flange height for grinding the planes, mm 50

– Max length of item when using steady rest for grinding the holes, mm350

Max weight of processed item, kg:

– loose quill 100

– clamped quill 500

– machining in chuck 100

Max length of table movement, mm – 995

Max angle of turning the top table, deg:

– in a clockwise direction 3o

– in a counterclockwise direction 8o

Motor power of item drive, kW 1,5

Dimensions of grinding disk (outer diameter х height х hole diameter), mm -600х80х305

Speed of cutting, m/s 50

Motor power of grinding disk drive, kW 11

Motor power of inside grinding device, kW 1,1

Dimensions, mm 5290х2580х2220

Weight (including electrical equipment, hydraulic unit and chilling plant), kg 7560

Accuracy class of 3Б722 machine is «П». Due to its adaptable design this machine allows to process items with dimensions not exceeding 100*36*40 cm. The distance from spindle to table surface can range from 19 to 63 cm.

Characteristics of spindle head:

– allowed size of the grinding disk – from 32,5 up to 45 cm.

– register diameter is 20,3 cm.

– max torque 6,7 kgf-m.

– transversal displacement – 40 cm;

– number of automatic feeds per one platen travel – from 1 to 30;

– maximum vertical displacement – 44см;

– parameters of automatic vertical feeds – from 0,005 up to 0,1 mm;

– speed of vertical accelerated displacement – 0,45 m/min.

The machine can operate in mode of automatic or manual feed.

Technical parameters working table:

– surface dimensions — 100*32 cm;

– dimensions of fixed electromagnetic chuck – 90*32 cm;

– longitudinal displacement – from 30 up to 105 cm;

– ability to adjust the speed of working table displacement– from 2 to 40 m/min.

Designed for sharpening basic cutting tools with the use of appropriate special tools. Applying special tools the machine can perform round (external and internal) and flat grinding.

Sharpening and grinding is performed when manual moving the tool with a table.

Specifications.

The largest diameter of the installed workpiece, mm – 250

The maximum length of the workpiece installed in the headstock, mm – 630

Height of centers, mm – 125

The distance between the centers of the universal and tail stocks, mm – 550

The distance between the axis of the grinding wheels and the line of centers, mm:

— in horizontal plane – 70-800

— in vertical plane – 65-165

Dimensions, mm – 2050х1820х1550

The weight of the machine with tool kit, kg – 1285

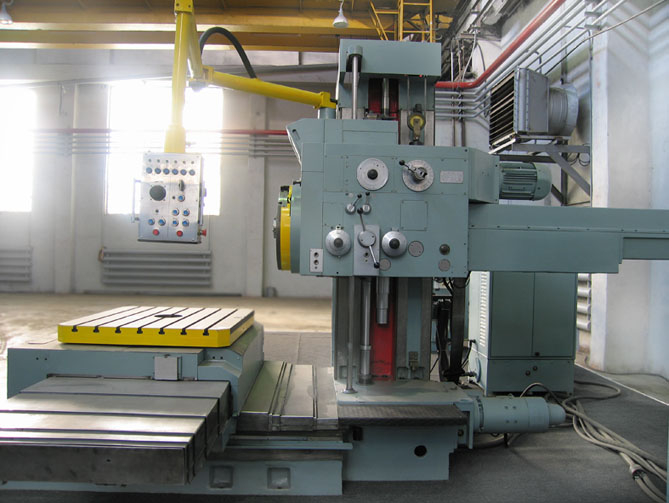

Designed for milling of planes, grooves, ledges; drilling, reaming, centering and countersinking holes; boring and reaming the holes; threading with taps; turning surfaces, machining of circumferential grooves and trimming ends

Dimensions of table working surface, mm 1250×1250

Table load, kg 3000

Spindle diameter, mm 110

Internal taper of Morse spindle No. 6

The max displacement, mm

– the headstock – vertically Y 1000

– the spindle, W 710

– the table – longitudinally, Z 1120

– the table – transverse X 1000

The spindle rotation speed, Rev/min 10-1250

Limits of working feeds, mm/min

X, Y, Z 1,4-1110

W 2,2-1760

Power, kW 7,5

Dimensions, mm 5700x3200x3000

Weight, kg 12500

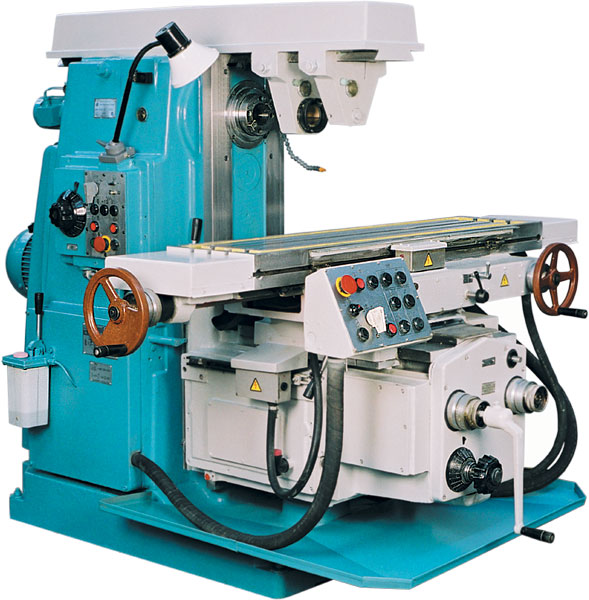

The main purpose of horizontal milling machine 6т83 is performance of various milling works by the use of cylindrical endmills and other cutters. It is used for milling angles, grooves, wheels, spirals, stamp and other workpieces made of various metals and their alloys.

Dimensions of table working surface, mm – 1600х400

The rotation of the table in both directions, deg – 45

Range of table feed, mm/min:

– longitudinal: 12,5-1600

– longitudinal : (stepless regulated) 5-3150*

– lateral: 12,5-1600

– transverse (stepless regulated) 5-3150*

– vertical 4,1-530

– vertical (stepless regulated)

Advanced traverse of table, mm/min:

– longitudinal – 4000

– transverse – 4000

– vertical – 1330

The limits of electric motors power, KW

– main spindle -11

– table feed – 3

Max weight of the processed workpiece with fixture, kg 1250

Machine dimensions, mm: 2570х2252х17780

Machine weight, kg 3900

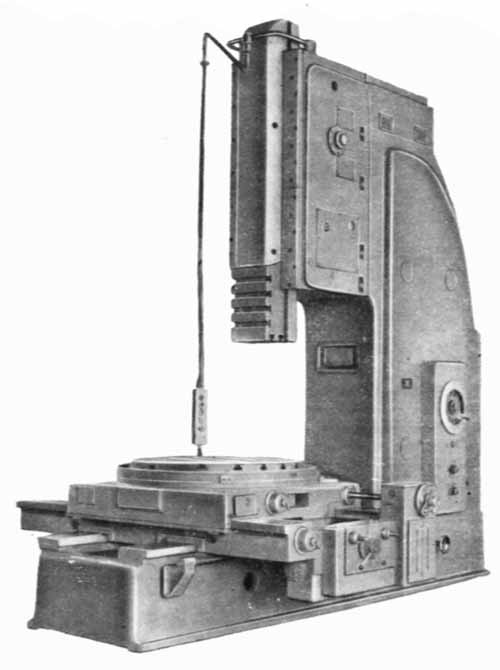

Machines of 7405 type are intended for external and internal slotting of flat and shaped surfaces, notches and grooves, as well as for slotting with undercutting up to 10 deg

Accuracy class: Н

Diameter of working table surface, mm – 800

Max travel of slotter rams, mm – 500

Power, kW: 11

Dimensions (L_B_H), mm: 3440_2760_3465

Weight of machine including removable accessories, kg: 8160

Machines of 745а type are intended for processing by slotting large hull and basic parts made of iron, steel and non-ferrous metals.

Accuracy class: Н

Diameter of working table surface, mm – 1250

Reach of the cutter holder, mm – 1150

Max travel of slotter rams – 1000

Power, kW: 28

Dimensions (L_B_H), mm: 4300х3120х5375

Weight of machine including removable accessories, kg: 17000

Machines of 7А420 type are intended for external and internal slotting of flat and shaped surfaces, notches and grooves, as well as for slotting with undercutting up to 10 deg,

Max travel of slotter rams, mm:

– min – 0

– max – 200

Diameter of working table surface, mm – 500

Advanced traverse of table:

– longitudinal, m/min – 1,8

– transverse, m/min – 1,8

– cilcular, deg. – 3,4

Dimensions, mm:

– length – 2300

– width – 1270

– heigth – 2175

Weight, kg – 2000

Max module of cut disk, mm – 12

Max diameter of cut spur gear, mm – 800

Max width of cut crown (length of cut), mm – 160

Diameter of slide separating disk, mm – 360

Slotter ram spindle:

– max travel of slotter ram (spindle), mm – 200

– max diameter of installed slotter ram, mm – 200

– advanced rotation speed of slotter ram, r/min – 3

Mandrel diameter for slotter ram, mm – 44,443

The end of the spindle for mounting the Morse tool – 5

Working table (faceplate):

– diameter of working table (faceplate), mm – 800

– advanced rotation speed of table, r/min – 1,7

– advanced travel speed of table, mm/min – 137

Drive and electrical equipment of the machine :

– the electric motor of the main drive – forward movement of the slotter ram (M1), kW – 7,5

– motor for rapid rotation of the slotter ram, kW – 0,8

– electric motor for table rotation, kW – 1,1

– electric motor for radial feed of the table, kW – 2,2

– electric motor for lubrication pump, kW – 0,25

– electric motor for cooling pump, kW 0,12

Dimensions and weight of the machine, mm : 3100 x 1800 x 3500

Weight including electrical equipment and chilling plant, kg: 10200

Max diameter of processed wheel in mm – 610,

The min and max module of the cut wheels, mm, 1-8

The min and max distance from spindle nose to the centre of the machine mm, 65-380

The max travel of the cutters in mm – 100

The maximum length of a cut gear in mm – 90

The min and max number of cut gears: 10-200.

Max and min values of half angle of the initial cone of the cut wheel, degree : 50°42′ and 84°18′

The number of double strokes per minute in the range of 85… 442

The number of feeds – 15

The processing time of a single gear: 7,6… 86,5.

Designed for cutting cylindrical and worm gear wheels in conditions of medium and large-scale production.

The max module of the cut wheels, mm – 10

The max diameter of cut worm wheels, mm – 800

The max diameter of cut cylindrical wheels, mm

— spur 800

— helical, at an inclination of:

— 30 deg– 500

— 45deg – 350

— 60 deg (cutter diameter 180 mm) – 120…250

Max length of cut cylindrical wheels, mm

— spur – 350

— helical, at an inclination of:

— 30 deg- 200

— 45 deg – 150

— 60 deg – 130

Min number of cut gears – 12

Max dimensions of cutting tool, mm

— diameter – 200

— length – 200

Max slide travel, mm – 380

Max angle of inclination of gears on processed gear wheels, degree: +-60

A tapered hole of Morse slide – 5

Main motor power, kW 7,5

The number of rpm – 1480

The number of cutter rotation stages – 9

Machine overall dimensions, mm – 2650х1510х2000

Weight of machine, kg 7200

Designed for cutting cylindrical and worm gear wheels in conditions of individual and serial production..

Max module of the cut whee l53А11, mm – 16

Max diameter of processed wheels 53А11(spur), mm:

– w/o support – 1250

– with support – 800

Min number of cut gears – 16

Max diameter of installed worm cutters 53А11, mm, – 225

Max vertical travel of cutter’s slide – 650

Maximum angle of gear inclination of processed wheels: +-45 deg

The size of the hole cone of the Morse spindle – 6

Maximum axial shift of the cutter 53А11, mm – 245

Table diameter 53А11, mm, – 1000

Rotation frequency of spindle, min- 28…270

Motors main drive:

– power, kW – 8; 10; 12.5

– rotation frequency, min – 671; 985; 1470

Overall dimensions of the machine 53А11, mm 4020х2350х2780

Weight of the machine 53А11, kg 17900

Designed for various milling operations in conditions of both individual and large-scale production. In mass production machines can be successfully used also for completion of operational works.

Dimensions, mm – 2565х2135х2235

Weight, kg – 4060

Dimensions of table working surface (length/width), mm1600/400

Shifting by single circle graduation, mm – 0,05

Spindle:

Inner cone – size№3

Max angle of rotation of the spindle head, deg±45

Turn on one scale division, deg – 1

Designed for drilling, reaming, countersinking, thread cutting; used in individual and serial production

Drilling capacity 18 mm.

Morse taper of spindle – 2

Maximum axial travel of the spindle is 150 mm.

Distance from spindle end to table:

– max – 650 mm.

– min – 0 mm.

S pindle movement per 1 rotation of the handwheel crank – 110 mm.

Max travel of spindle head 300 mm.

Maximum vertical travel of table is 350 mm.

The width of the working surface of the table 320 mm.

The length of the working surface of the table 320 mm.

Number of spindle speeds – 9

Power – 1.5 kW.

The number of rotations per minute -1420

Machine dimensions , mm-870x590x2080

Weight of machine kg 450

Designed for drilling, reaming, countersinking, thread cutting; used in individual and serial production.

Accuracy class Н

Max diameter of drilling in steel 45 GOST 1050-74, mm 35

Size of the spindle cone as per GOST 25557-82 Morse 4

Max spindle travel, mm 250

Max move of the drilling head, 170 mm

The travel of the spindle during one rotation of the wheel, mm 122.46

Working table surface, mm 450×500

Max travel of table, mm 300

The distance between the two T-slots according to GOST 6569-75, mm – 100

Quantity of speed modes – 12

The frequency limits of spindle rotation, 1/min 31,5-1400

Number of feeds – 9

Max number of cut holes per hour 55

Overall dimensions, mm:2535х825х1030

Weight of machine, kg – 1200

Designed for processing high speed cutting metals with tools made of high speed steel and hard steels..

Accuracy class of the machine according to GOST 8-82 (Н,П,В,А,С) : H

Diameter of workpiece over bed, mm – 1000

Diameter of the workpiece over support, mm – 600

Length of workpiece, mm – 2800/5000

Limits of spindle rotation frequencies, Min/Max, R/min – 5 ; 500

Main motor power, kW. – 22

Dimensions of machine: mm. 5825х2100х1760

Weight of machine, kg 12500

Machine 1М63 is of “Н” accuracy class. It can grind products with a diameter of up to 35 cm (over the support) and 63 cm (over frame). The maximum length of the part for machining – 140 cm, centre height – 31.5 cm.

Spindle of 1М63 machine rotates at frequencies from 18 to 1800 rpm (reverse) and from 10 to 1250 rpm (forward). A braking system of a spindle device is characterized by 11 reverse and 22 forward speed modes. The cross-section of the hole in the spindle is equal to 7 centimeters.

1М63 support characterisrics:

– maximum movement in the longitudinal direction -126 cm, the cross – 40 cm;

– the number of cutters is 4 (you can simultaneously use all four tools, which are installed in a tool head of the machine);

– the distance between the edge of the cutter holder and the axis of the centers – 32 cm;

– rapid traverse – 4.5 m/min for longitudinal stroke along the guide frame, and 1.6 m/min for transverse stroke along the carriage guide;

– one limb scale unit is 1 and 0.05 mm (longitudinal and transverse motion);

– the movement of the support at full turn of the scale – 5 mm (in the transverse direction) and 300 mm (in longitudinal).

– the minimum and maximum spindle rotation is 12.5/1600 rpm;

– the ultimate cross-section of the workpiece is thirty-one cm over a landing slot, 22 on the support 40 in the area of the frame;

– step distance is from 0.5 to 56 units;

– maximum length of the item is two meters; longitudinal and cross number of feed changes is 24 and 22 r;

– maximum weight of workpiece – 1.3 tons;

– spindle hole section – fifty two mm;

– number of speed modes – 22.

Designed for various turning works on the centers and in chuck.

Accuracy class – Н

Main gear motor power, kW – 11

The spindle rotation frequency min/max, R/min – 8,5/2 000

Diameter of processed item over the frame, mm – 500

Length of processed item, mm – 1000

Dimensions, mm – 3850х1250х1605

Weight, kg – 2 950

Is designed for grinding external and internal cylindrical or conical surfaces by means of plunge-cut and longitudinal grinding and also for grinding of flat surfaces of parts such as washers and for grinding the ends.

Accuracy class as per GOST 11654-84 … В

Max diameter of grinding, mm … 280

Max length of grinding, mm… 1000

Max weight of the processed item, kg:

– loose quill… 55

– clamped quill… 300

– in chuck… 40

– in chuck with work rest device… 50

Max table travel, mm … 1000

Max angle of turning the grinding head, deg … +-30

Diameter of grinded hole, mm … 15 – 100

Max length of grinded hole, mm … 125

Dimensions, mm: 4975х2605х2200

Weght, kg … 6600

Is suitable for transportation of heavy-weight cargos at the required dictance.

Load capacity 430 t

Platform dimensions: Length 21 m, width 7 m.